Why do we need to conduct battery charging and discharging tests?

I. What is Battery Charge and Discharge Testing?

Battery charge and discharge testing is an important testing method used to evaluate the performance and capacity of batteries. It measures and analyzes the battery's energy storage and release capabilities by simulating the charging and discharging processes of the battery in actual use.

II. The Workflow of Charge and Discharge Testing

During the charging test stage, connect the battery to the charger, adjust the charger's current and voltage, and start charging. Generally, a constant current and constant voltage charging mode is adopted during the charging process until the battery is fully charged.

The discharge test involves connecting the battery to the load, adjusting the load resistance and current, and starting the discharge. The discharge current should be tested according to the standards required by the manufacturer, usually 1/5 or 1/10 of the battery capacity. The discharge time is typically 1 to 20 hours of the battery capacity, and it can be adjusted according to the actual situation. During the discharge process, it is necessary to pay attention to reaching the battery's cut-off voltage to avoid damaging the battery.

In addition, in-depth testing is also an important part of battery charge and discharge testing. This includes high-temperature and low-temperature tests, as well as cycle tests. In the high-temperature test, after the battery is fully charged, it is placed in a constant temperature chamber, the temperature is adjusted to 65°C, and it is left for 4 hours before the discharge test. Observe whether the capacity can reach more than 85% of the nominal capacity. The low-temperature test is carried out in a similar operation in an environment of -20°C, and observe whether the discharge capacity can reach more than 60% of the nominal capacity. The cycle test is to observe the battery's capacity attenuation by performing multiple charge and discharge cycles.

III. The Main Purposes of Battery Charge and Discharge Testing

Understand the Charge and Discharge Characteristics of Batteries: The characteristics of the battery will change during its charge and discharge processes, including changes in parameters such as voltage, current, and capacity. Through charge and discharge testing, a deeper understanding of the battery's charge and discharge characteristics can be obtained, providing important basic data for the normal operation of the battery.

Evaluate Battery Performance: Charge and discharge testing can evaluate a number of performance indicators of the battery, such as capacity, internal resistance, discharge platform, and constant current discharge. This helps to promptly identify and fix existing problems in the battery, improving the battery's service life and stability.

Ensure the Normal Operation of the Battery: During the use of the battery, it may be affected by external factors such as temperature, humidity, and uneven charging and discharging. Charge and discharge testing can promptly detect these factors that may affect the normal operation of the battery, thereby ensuring the normal operation of the battery and improving the service life and stability of the equipment.

Evaluate the Battery's Cycle Life and Discharge Performance: The battery discharge test is crucial for evaluating its cycle life and discharge performance. Through the test, the performance degradation of the battery during long-term use and its performance under different discharge conditions can be understood.

IV. The Advantages of Battery Charge and Discharge Testing

Comprehensively Evaluate Battery Performance: Through charge and discharge testing, key performance parameters of the battery, such as capacity, internal resistance, and charge and discharge efficiency, can be accurately evaluated, thus comprehensively understanding the battery's performance status.

Discover Potential Problems: During the testing process, various conditions of the battery in actual use can be simulated, helping to discover potential performance problems or safety hazards, such as overcharging, over-discharging, short-circuiting, etc., providing a guarantee for the safe use of the battery.

Optimize Battery Use and Management: According to the test results, the battery's charging strategy, discharge mode, and maintenance cycle can be optimized, improving the battery's use efficiency and extending its service life.

Support R&D and Design: For battery R&D personnel, charge and discharge testing can provide valuable data support, helping them to improve battery design and enhance battery performance.

V. The Disadvantages of Battery Charge and Discharge Testing

Long Testing Time: For large-capacity batteries or batteries that require multiple cycle tests, the charge and discharge testing may take a long time, which will affect production efficiency.

High Testing Cost: Charge and discharge testing requires the use of professional testing equipment and consumes a certain amount of electrical energy and other resources, so the testing cost is relatively high.

Limitations of Testing Conditions: Although the testing can simulate various conditions, it is difficult to completely simulate all factors in the actual use scenario, such as temperature, humidity, vibration, etc., which may lead to a deviation between the test results and the actual use performance.

Potential Impact on Battery Life: Frequent charge and discharge testing may have a certain impact on the battery life, especially under relatively harsh testing conditions.

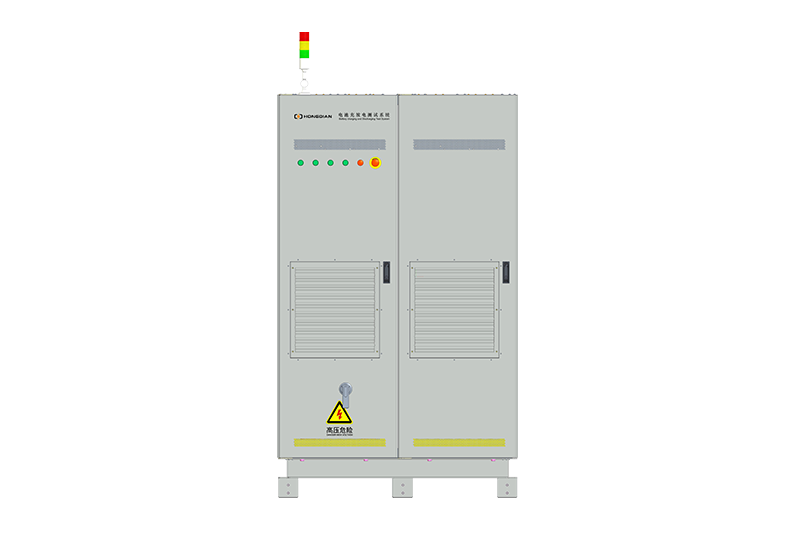

1000V-1500V High Voltage High Current Battery Testing System

1000V-1500V High Voltage High Current Battery Testing System

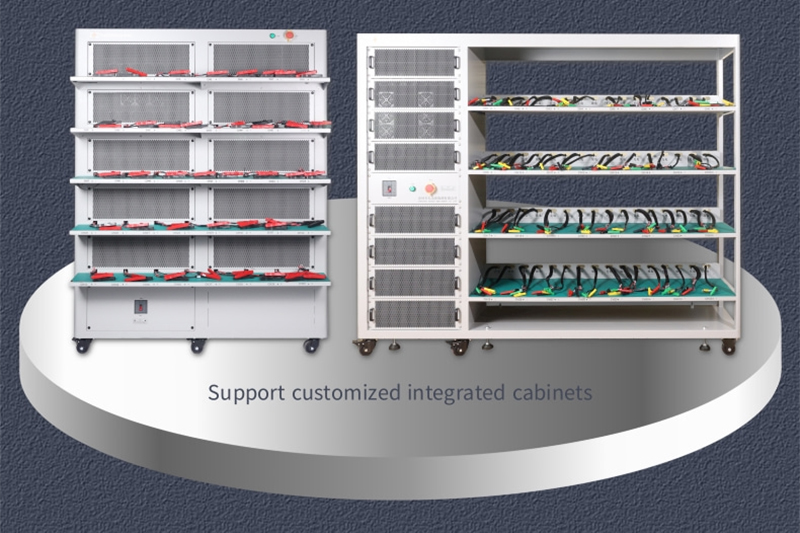

32/48 channel battery charging and discharging test integrated battery cabinet

32/48 channel battery charging and discharging test integrated battery cabinet

40 channel battery charging and discharging test integrated battery cabinet

40 channel battery charging and discharging test integrated battery cabinet

64 channel battery charging and discharging test integrated battery cabinet

64 channel battery charging and discharging test integrated battery cabinet

80 channel battery charging and discharging test integrated battery cabinet

80 channel battery charging and discharging test integrated battery cabinet

High-Precision Battery Testing System for Enhanced Performance Monitoring 30V/60V/100V/120V

High-Precision Battery Testing System for Enhanced Performance Monitoring 30V/60V/100V/120V

High-Precision Battery Charge Discharge Test Systems for EV Manufacturers

High-Precision Battery Charge Discharge Test Systems for EV Manufacturers

Precision Battery Test Racks for Cell Capacity & Internal Resistance Measurement

Precision Battery Test Racks for Cell Capacity & Internal Resistance Measurement

Multi-Channel Battery Testing Equipment for Parallel Performance Analysis

Multi-Channel Battery Testing Equipment for Parallel Performance Analysis